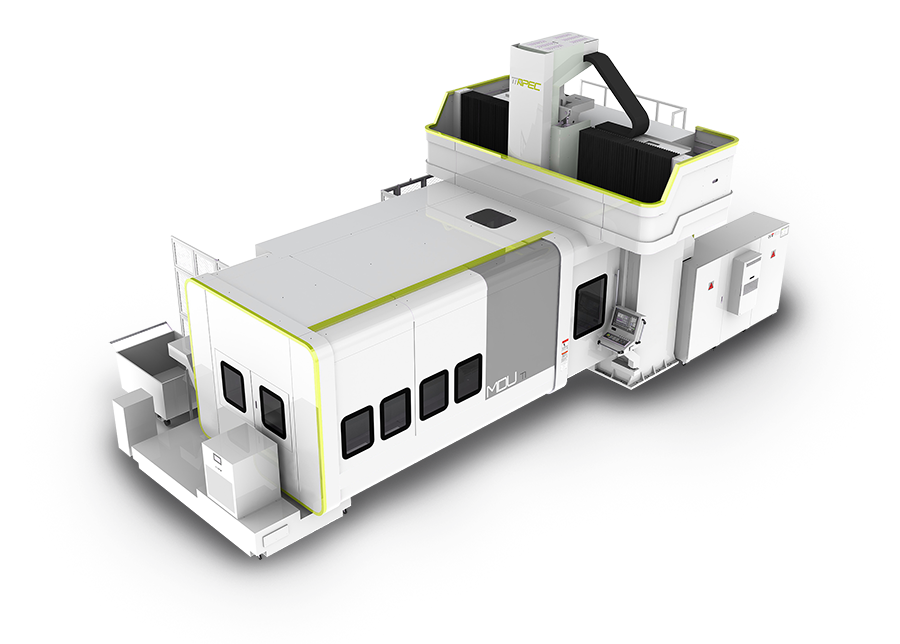

Bridge Type

Aerospace SuperAlloy DedicatedHeavy duty 5-axis machining center

MDU-Titan series

-Special for superalloy processing

-U-shape structure design

-Fully enclosed splash guard

-U-shape structure design

-Fully enclosed splash guard

- U-shape structure design

One-piece U-shaped and high rigid structure enhances long-term accuracy and stability thanks to the shortest transmission of the force flow and evenly distributed cutting force.

The column and beam of the super-large surface casting have double cross-sectional area than the general gantry machine which greatly improves the rigidity and stability.

Fully enclosed splash guard

In order to avoid the splashing of cutting fluid and metal flying debris, MDU-Titan uses a fully dense sheet metal shield for all-round protection.

X / Y / W axis Driven by high-speed ball screw

Precision ball screws have the advantages of low noise, space saving and lightweight design, high acceleration and deceleration, high precision, and high reproducibility. They provide better working quality for high lead and large diameter ball screws.

*Please contact our sales if you have a special requirement.Specification Unit MDU-Titan X-axis mm 4,200 Y-axis mm 2,800 Z-axis mm 1,000 Distance from spindle end to table mm 350-1,350(vertical)

620-1,620(horizontal)Table Length× Width: Load mm 4,000×2,060:8T Rapid traverse m /min X/Y=20, W= 12 Spindle taper HSK100A Spindle speed rpm 6,000 Spindle power(S1/S6) kW 37 Spindle torque(S1/S6) Nm 1,000 Tool shank pcs 32T Max. tool length mm 350 Max. tool diameter with

adjacent toolmm Ø125 Max. tool diameter

without an adjacent toolmm Ø250 Weight tons. 20

*All specifications and designs are subject to change without notice.