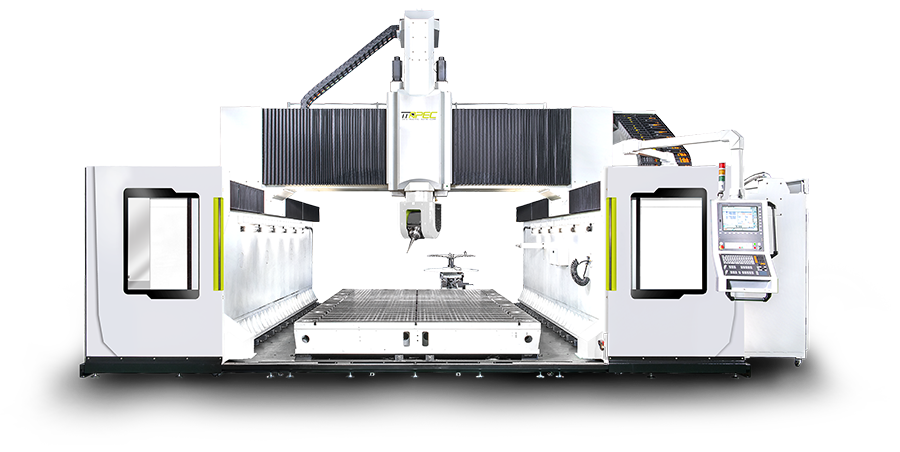

Gantry Type

Aerospace Composite Dedicated5-axis High-Speed Gantry Machining Center

CM series

-For aerospace composite processing

-Dust collecting and filtering system

-Xaxis driven by rack and pinion

-Y/Z-axis driven by ball screws

-Dust collecting and filtering system

-Xaxis driven by rack and pinion

-Y/Z-axis driven by ball screws

Dust collecting & filtering system for working area and spindle nose

The NC controllable telescopic dust suction hood can stretch automatically by NC code or M function, and won’t interference tool changing.

NC controllable top roof sliding coverIt can prevent the oil mist and dust from overflowing the processing area to protect the health of the operator and the keep air quality.

*Please contact our sales if you have a special requirement.Specification Unit CM3040 X-axis mm 4,000 Y-axis mm 3,000 Z-axis mm 1,500 Rapid traverse m /min XY=30 Z=20 Spindle taper HSK63F Spindle speed rpm 28,000 Spindle power

( S 1 / S6)kW 20/25 Spindle torque

( S 1 / S6)Nm 32/40 Recommended 2-axis head Mono Support Milling Head Swivel/Rotation Torque Nm A=133/286

C=66.2/128Swivel/Rotation Speed rpm A=C=100(cont) Swivel/Rotation Angle deg A=±110°~±125° C=±360° Tool shank pcs 20T Max. tool length mm 300 Max. tool diameter with

adjacent toolmm Ø70 Weight tons. 35-65

*All specifications and designs are subject to change without notice.