September 25

2025

Mastering Titanium: From Heat to High Precision

#DidYouKnow …

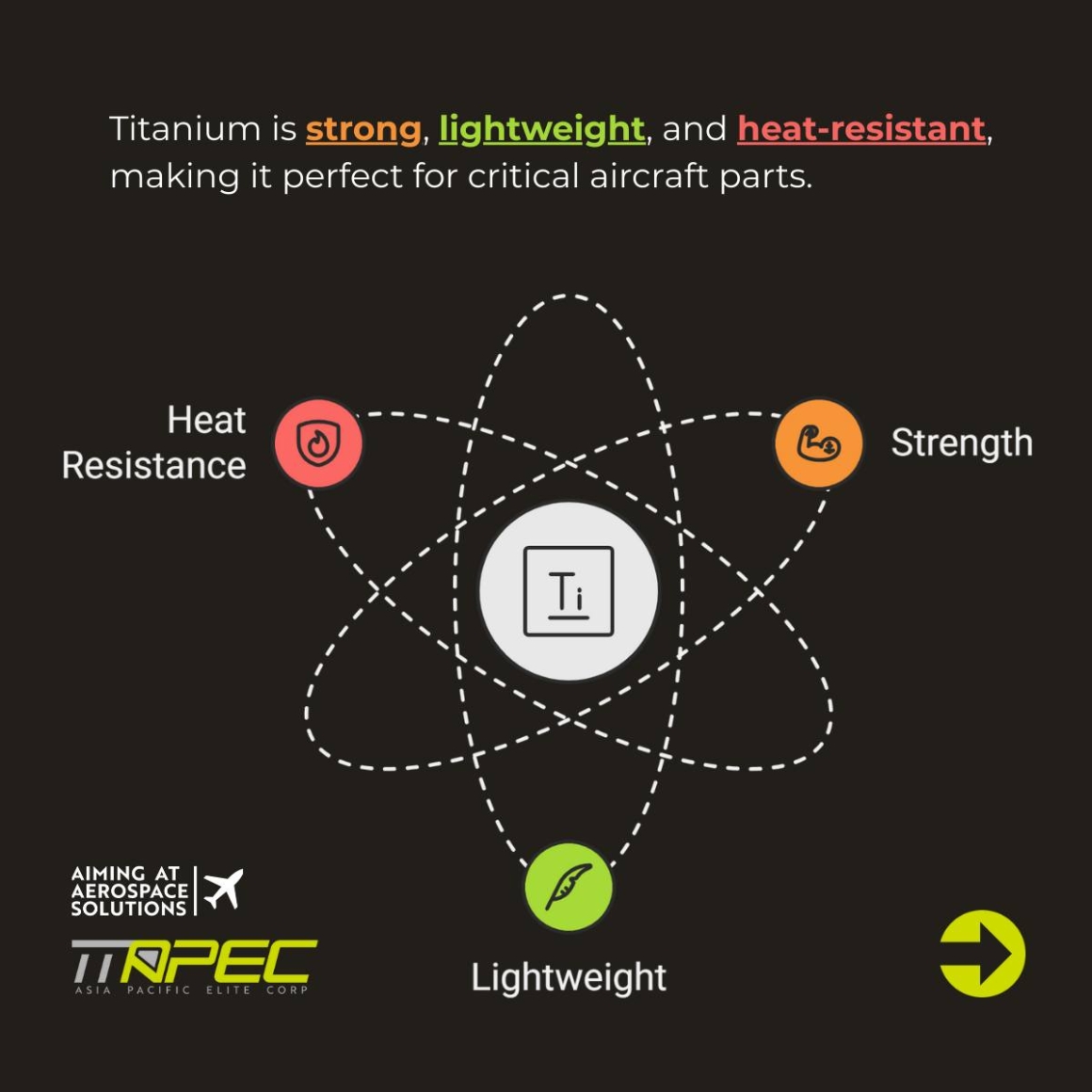

#DidYouKnow …Titanium is aerospace’s favorite metal — strong, lightweight, and heat-resistant.

Perfect for aircraft parts… but also a machinist’s toughest challenge.

Why? Its low thermal conductivity traps cutting heat at the tool, not the chip, causing faster tool wear and tougher machining.

Still, titanium is irreplaceable in aerospace, from turbine blades to structural components.

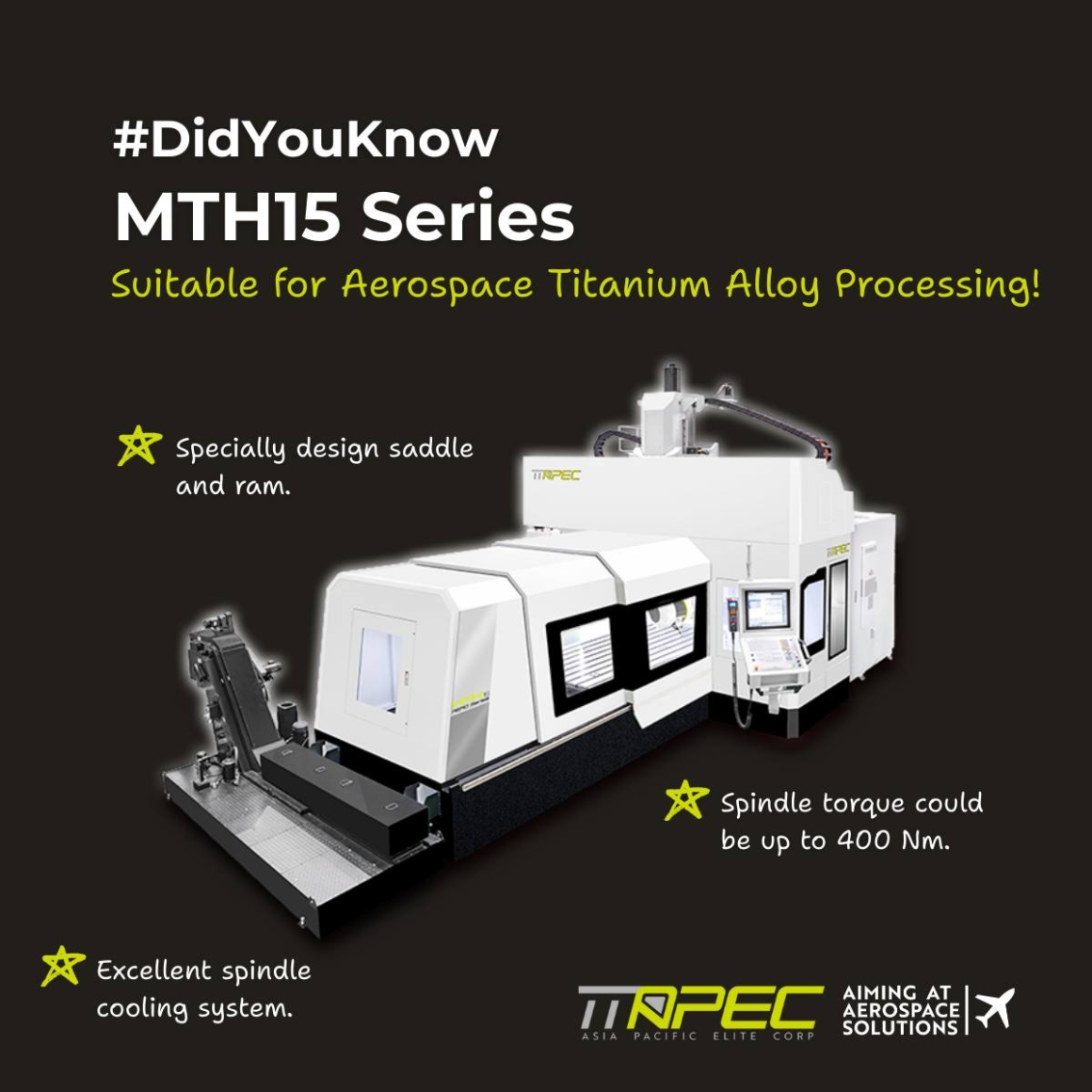

That’s why TTAPEC’s MTH15 Series is specially engineered for titanium alloy processing — with up to 400 Nm spindle torque and an advanced cooling system to handle the heat.

MTH15 Series:

https://www.apeccnc.com/en/products-detail/ProductMTH/

Related News

-

January 222026

Less Vibration. More Control.