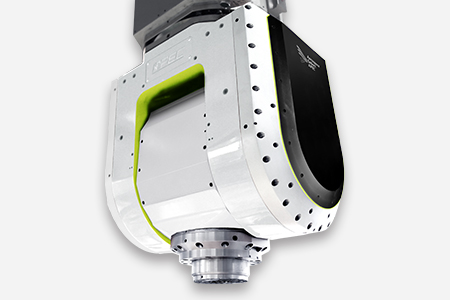

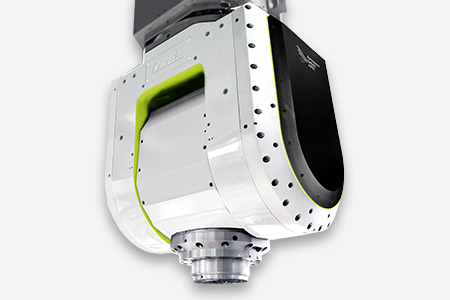

Fork Type Milling Head

-High torque clamping system

-High rigidity machining with fork-type structure design. Dual brake and double torque motor-driven systems offer the best stability.

-Direct torque motor provides high dynamic characteristics at high speed swiveling 30 rpm.

(Reduce non-machining time and increasing production efficiency.)

-Ring-type optical linear scale in B and C axis offer the best stability instead of mechanical transmission.

-The rigid mechanism ensures accurate position feedback and reduces the vibration.

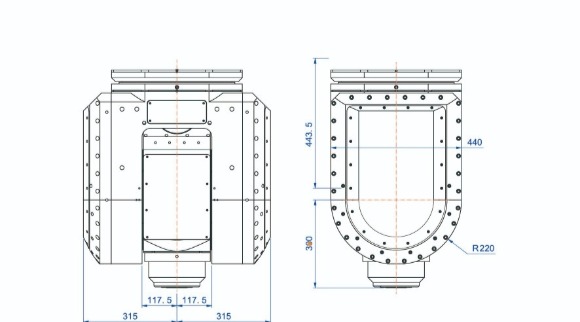

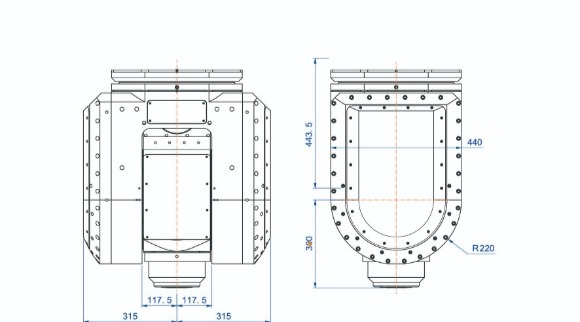

| Spindle taper | HSK63A/HSK100A | Tool Clamping | Auto Clamping |

| Swivel/Rotation Torque | B=1,192/1,980Nm C=1,050/1,740Nm |

||

| Swivel/Rotation Speed | B=C=30(cont)/60(max)rpm | Indexing | Continuous |

| Swivel/Rotation Angle | HSK63A:B=±120° C=±360° HSK100A:B=±115° C=±360° |

Clamping Torque | B=4,000Nm C=4,000Nm |